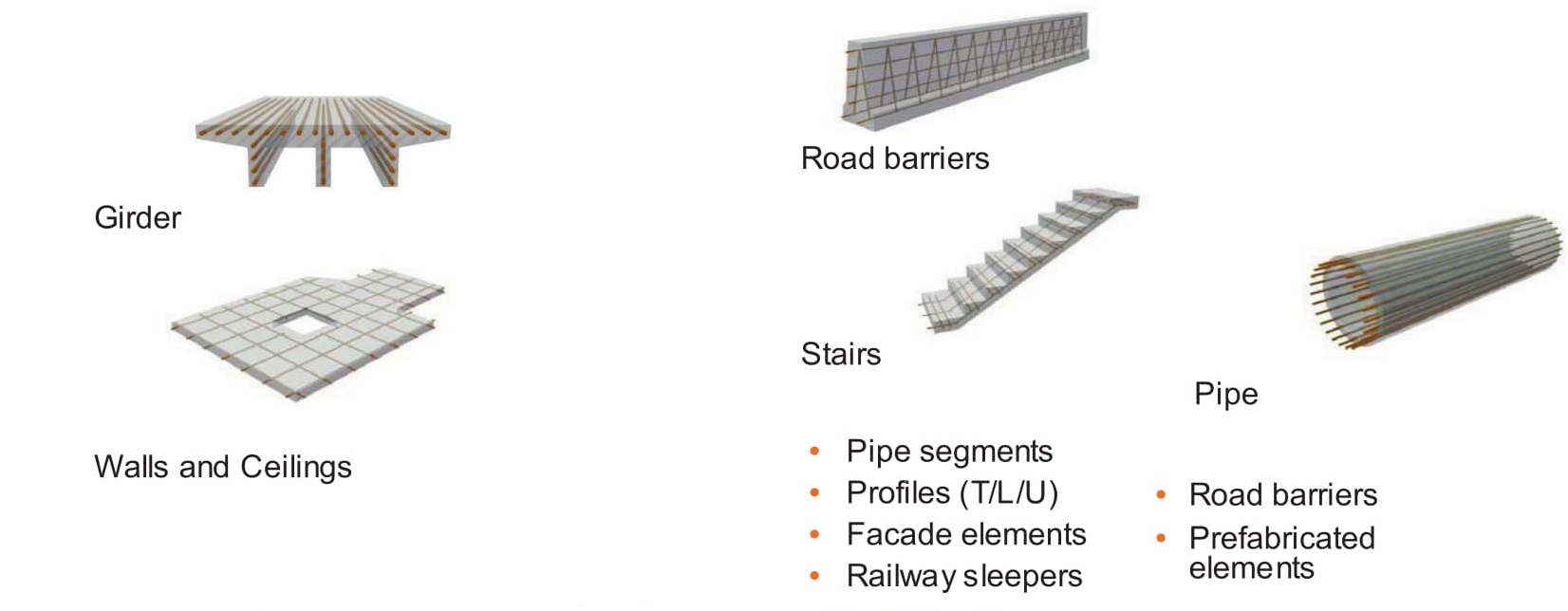

Precast concrete elements

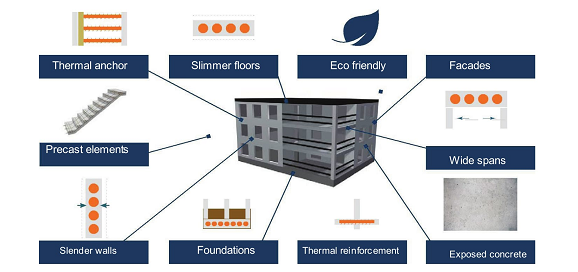

Lower cost and shorter construction periods is of paramount importance in modern construction projects. For this reason, use of precast concrete sections has become common-place in todays construction sites. The requirement for lower costs and shorter times however, do not mean that quality and workmanship can be compromised. This adds ever more increasing demands for prefabricated precast concrete elements. Due to its advantages,GFRP Technologies is an ideal reinforcement for these elements.

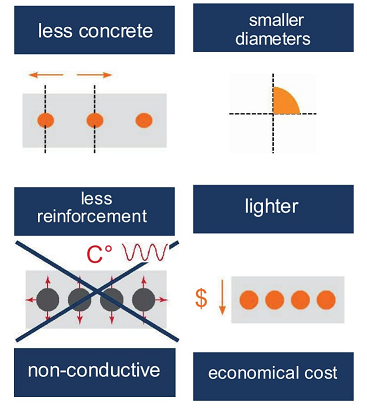

Another great advantage of GFRP Technologies is the significantly reduced amount of reinforcement and concrete cover. This results in much lighter elements, creating design freedom and more importantly, cost savings.

• Pipe segments

• Profiles (T/L/U)

• Facade elements

• Railway sleepers

• Road barriers

• Prefabricated elements